Ultrasonic welding of non-ferrous metals such as copper and aluminum is the proven welding technology in the industry for many years. it only takes 1 to 3 seconds for ultrasonic welding. Compared to other welding methods, ultrasonic welding generates lower temperature raising on joint area, and this is the most important advantagel. For example, the insulation materials does not damage in the vicinity due to welding, and the joint does not crack. The joint area has higher bonding after the atomic layer relaxation process of ultrasonic welding. This welding method is similar to diffusion welding.

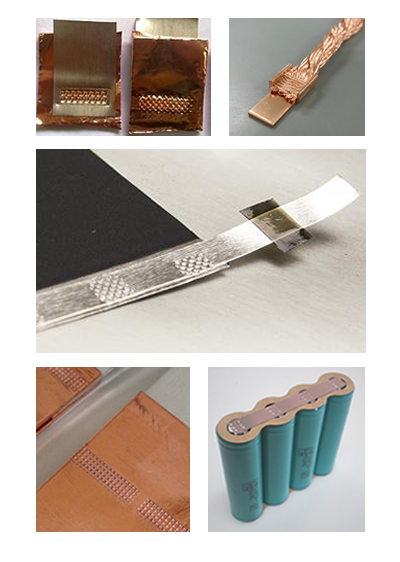

There are variety applications in the field of ultrasonic metal welding. Including simple wire and bus connections, wiring harness and contact welding in the automotive and electronics fields, and special applications for enamelled winding wires, films and sheets.