Ultrasonic technology in the packaging industry has become increasingly popular. Different containers, such as squeeze tubes, bottles, bags, transparent plastic cover, etc. can be welded, perforated, cut and sealed by means of ultrasonics. Whether the contents of the container is sensitive to high temperature changes, compared to many other technologies, the contents are not afftectd by ultrasonic sealing. Ultrasonic sealing is a very economical technology, will not make the contents been heated. There is no temperature rising problem in the process will not temperature rise and no additives is required. The items will not be contaminated in the welding process. Ultrasonic seal is energy-saving and environmental-friendly. Tthrough a highly developed technology, processing speed and quality can be greatly enhanced. Parts within welding area can be firmly sealed with perfect quality.

Advantages for packaging industry

- Greatly reducing the processing time, plastic parts can be sealed within a few milliseconds

- With ultrasonic processing, the energy is consumed only with the welding area. The process is clean, stable and reliable, and low energy consumption

- Preheating and insulation are not required, excess heat is not generated during the process

- Without the use of expensive and contaminated accessories such as adhesives or spikes, the processed packaging can be recycled

- Even if there is dirt (such as liquid, grease, powder, etc.) can still be sealed

- Ultrasonic equipments and its components are easy to install in automation production and are compatible to conveyor systems

- With high grade ultrasonic generators or external controllers, it is possible to make accurate setup. In addition to build database for various packaging materials, it adding multiple advanced control and alarm system can ensure the operation and optimization of output products

Compatibility of Common Packaging Materials

| Material |

Coating |

Sheet |

Film |

Foam |

| Ionomer ( SurlynR ) |

G |

G |

G |

- |

| PET / PETE |

- |

- |

- |

E |

| PETG / RPET |

- |

- |

- |

E |

| Polyethylene |

E |

E |

E |

- |

| Polypropylene |

E |

E |

E |

E |

| PVA |

G |

G |

G |

- |

| PVC |

G |

G |

G~P |

E~G |

| Styrene |

G |

G |

G |

E |

| Urethane |

E~G |

- |

E~G |

- |

REMARK: E = excellent , G =good , F =normal, P = bad, - = not suitable for ultrasonic processing

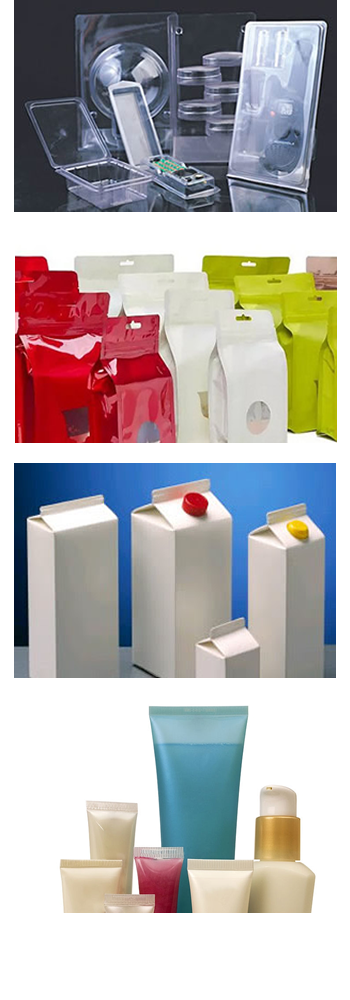

Applications of ultrasonic sealing

- Blister

- Pouch forming and sealing

- Coated carton sealing

- Tube end sealing

- Film (same material) laminating