High frequency generates an eddy current in the aluminum layer, which heats up the aluminum and adjacent plastic layers. While the temperature reaches the melting degree of plastic, clamps are closed and melted plastic is cooled and formed. Tube sealing is completed. This sealing is for production of medium capacity.

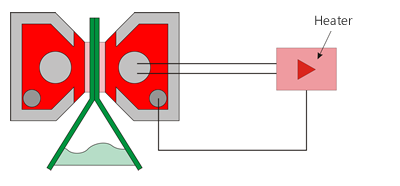

Heated jaws apply heat on the outside of the tube to heat up the inside for sealing. This process is less efficient than High-Frequency Sealing. This method is for production of small to medium capacity.

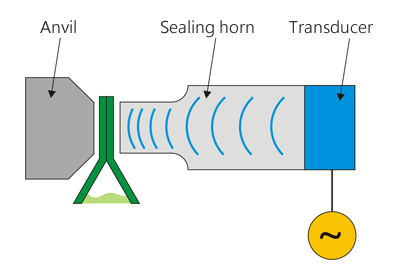

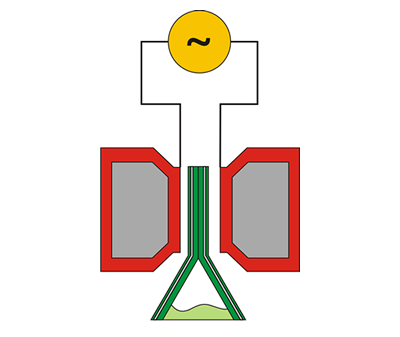

The plastic inside the tube is heated and melted by high frequency friction force introduced from ultrasonic horn. Clamps closed and cooled and formed the melted plastic to seal the tube. This methos is suitable for production of small to medium capacity.